Nous utilisons des cookies !

Notre site web utilise des cookies. Nous les utilisons pour vous offrir une meilleure expérience de navigation, analyser le trafic du site, personnaliser le contenu et diffuser des publicités ciblées.

Pour en savoir plus sur la manière dont nous utilisons les cookies et comment les gérer, cliquez sur « Paramètres des cookies ».

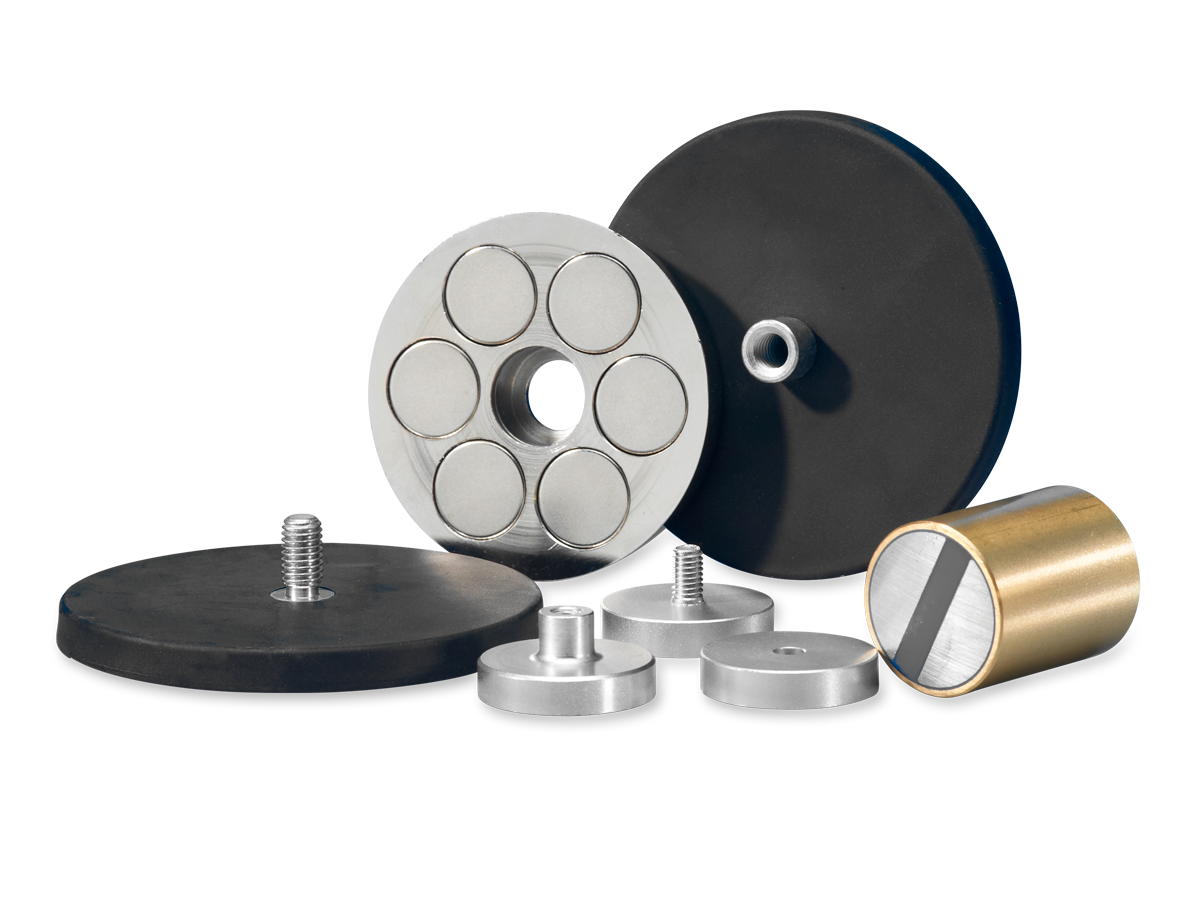

Plots magnétiques plats

Résultats de la recherche

Vos résultats dans : pages, produits et documents

Faites défiler pour tout voir. Vous n'avez pas trouvé ce que vous cherchiez ?

Essayez un autre terme de recherche ou contactez-nous.

Aucun résultat trouvé

-

{{filter.Description}}

({{filter.UOMDescription}})

Aucun résultat trouvé

Vos résultats dans : pages, produits et documents

Faites défiler pour tout voir. Vous n'avez pas trouvé ce que vous cherchiez ?

Essayez un autre terme de recherche ou contactez-nous.

Plots magnétiques en néodyme

Composition et structure des plots magnétiques en NdFeb

Ces plots magnétiques très résistants sont composés de l’alliage néodyme-fer-bore (NdFeB), connu chez Goudsmit sous le nom déposé Neoflux®. La gaine offre un cloisonnement magnétique. Goudsmit propose des plots magnétiques en néodyme avec une gaine en laiton ou en acier. La surface adhérente est couverte d’une laque protectrice pour éviter la corrosion.

Court-circuit magnétique

Afin d’éviter la perte de la force d’adhérence en raison d’un court-circuit magnétique, les aimants en néodyme avec une gaine en laiton ne peuvent pas directement être poussés dans l’acier. Conservez toujours une distance minimale entre la gaine en laiton du pot magnétique et l’acier. Pour obtenir des conseils, veuillez contactez nos experts, qui se feront un plaisir de vous aider.

Température de fonctionnement et perte de force magnétique

Les plots magnétiques cylindriques et plats en néodyme ont une température de fonctionnement maximale de 80 °C. Lorsqu'il est chauffé à cette température, l'aimant perd 15 à 20 % de sa force magnétique. Cette perte n'est pas permanente et la force est rétablie lorsque l'aimant revient à la température ambiante normale.

Des champs magnétiques externes peuvent également provoquer une perte de force magnétique. Un entrefer ou des matériaux non magnétiques situés entre l'aimant et la pièce réduisent la force de traction.

Pots magnétiques en ferrite

Composition et structure de pots magnétiques en ferrite

Bonnes propriétés magnétiques, prix abordable. Les pots magnétiques en ferrite, également appelés pots magnétiques en céramique, sont pourvus d’un pot en acier qui assure le cloisonnement du champ magnétique. Les pots magnétiques plats en ferrite ne nécessitent qu’une hauteur d’installation minimale. Cela offre des avantages en matière de construction. Les pots magnétiques en ferrite résistent à la corrosion et ne nécessitent donc pas de revêtement supplémentaire sur la surface de l’aimant.

Température de fonctionnement et perte de force magnétique

Les pots magnétiques en ferrite ont une température de fonctionnement maximale de 200 °C. Lorsqu’il est chauffé à cette température, l’aimant perd 30 à 40 % de sa force magnétique. Cette perte n’est pas permanente et la force est rétablie lorsque l’aimant revient à la température ambiante normale. La force magnétique de ces pots magnétiques est inférieure à celle des pots magnétiques en néodyme.

Des champs magnétiques externes peuvent également provoquer une perte de force magnétique. Un entrefer ou des matériaux non magnétiques situés entre l’aimant et la pièce réduisent la force de traction.

Pots magnétiques en samarium-cobalt

Composition et structure des pots magnétiques en SmCo

Deuxième type d’aimant le plus fort. Les pots magnétiques en samarium-cobalt (SmCo) offrent une combinaison unique de grande puissance magnétique et de température d’utilisation élevée. Ces pots magnétiques ultra solides sont composés d’un alliage de samarium et de cobalt. La force d’adhérence à température ambiante est cinq fois supérieure à celle des pots magnétiques en ferrite.

Les pots magnétiques en samarium-cobalt sont, après les pots magnétiques Neoflux®, les plus résistants de notre assortiment.

Installation et démagnétisation

Les pots magnétiques en samarium-cobalt sont très stables et difficiles à démagnétiser dans un champ magnétique à variation rapide. Le pot en acier n’offre aucun cloisonnement magnétique. C’est la raison pour laquelle ces pots magnétiques ne peuvent pas être intégrés tels quels dans des éléments en acier. La distance entre l’élément en acier et le pot magnétique en samarium-cobalt doit s’élever à 1,5 à 6 mm, en fonction de la taille du pot magnétique.

Température de fonctionnement et perte de force magnétique

Les pots magnétiques en samarium-cobalt ont une température de fonctionnement maximale de 200 °C. Lorsqu’il est chauffé à cette température, l’aimant perd 15 à 20 % de sa force magnétique. Cette perte n’est pas permanente et la force est rétablie lorsque l’aimant revient à la température ambiante normale.

Des champs magnétiques externes peuvent également provoquer une perte de force magnétique. Un entrefer ou des matériaux non magnétiques situés entre l’aimant et la pièce réduisent la force de traction.

Systèmes magnétiques compacts et plats disponibles en néodyme, en samarium-cobalt, et en ferrite. Convient pour le collage. Grâce à la gaine de ces systèmes magnétiques, le champ magnétique augmente et les plots magnétiques résistent mieux à la corrosion ou aux produits chimiques. Les plots magnétiques ont une seule surface d’attraction. Ceci empêche la dispersion du champ magnétique.

Les forces de prise indiquées sont mesurées dans des conditions optimales : verticalement, sur un morceau d’acier 37 poli avec une épaisseur de 5 mm, sans entrefer.