Automatic external pole magnet for feed and bulk goods

The automatic external pole magnet, recently developed by Goudsmit, is suitable for processing large capacities of feed and bulk goods. The magnet can be used for intake in ship unloading installations and serves to protect the machinery. Moulds, grinding and mixing equipment can be damaged by undesired metal particles. The external pole magnet is intended for coarse separation and separates parts larger than 1 mm. Magnetic bars are suitable for the separation of finer metal particles. Fully automatic cleaning is integrated into the process system and takes place at the push of a button, without the intervention of an operator. The low built-in height of 600 mm makes the system easy to build into existing installations.

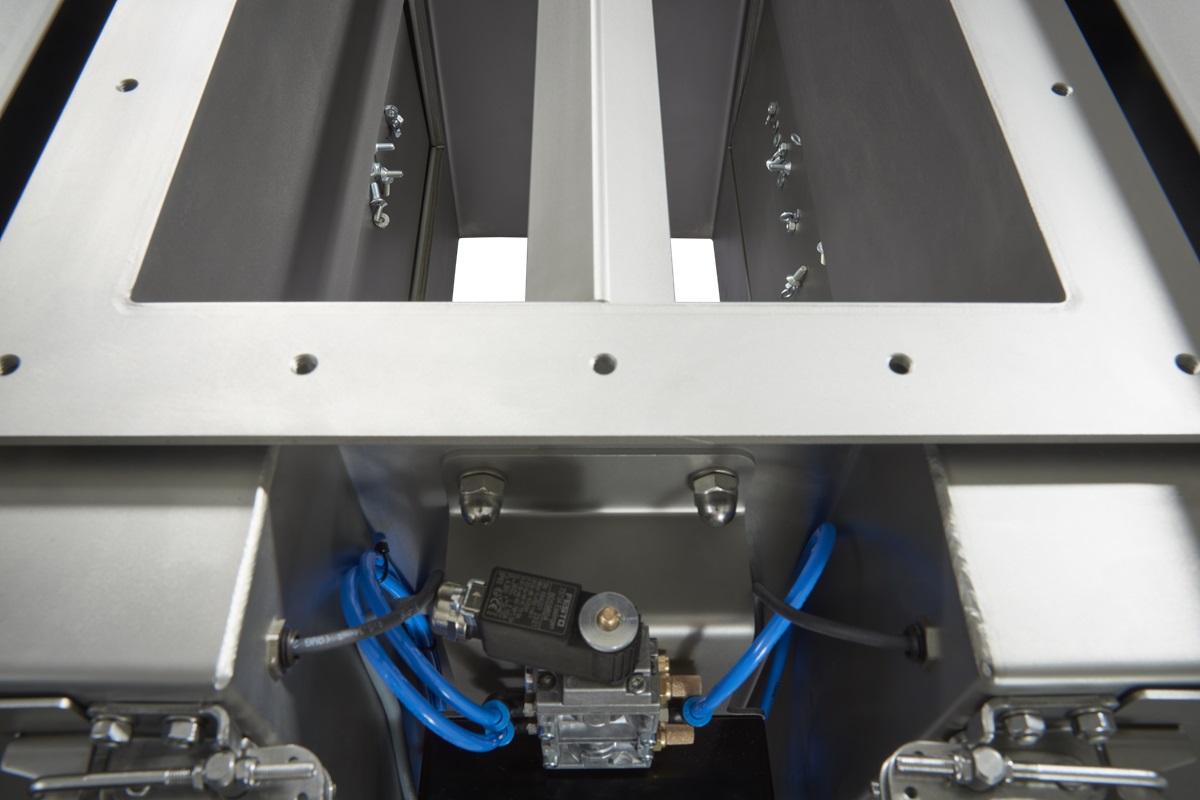

Free fall line

Two powerful capturing magnets are mounted on the outside of the completely smooth casing and, depending on the version, separate coarse or very fine iron particles from various material streams. The outer core magnet is fitted with Neodymium-Iron-Boron (NdFeB) magnets for mounting in free-fall lines. An advantage of this outer-core assembly is that no bridging or clogging of the material can take place on the inside. Since the cleaning is fully integrated in the design, the installation height remains limited.

Application

Application of such magnets is in ship unloading installations, at intake, in filling lines or for loading silos. A pneumatic controller ensures cleaning of the magnet. This is started via a 24V-DC signal and then runs fully automatically. The external pole magnet is available in various versions up to an inlet/outlet of 300x1200 mm. It is suitable for large capacities up to 600 m3/hour.