Magnetic filters - hygienic - manual

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

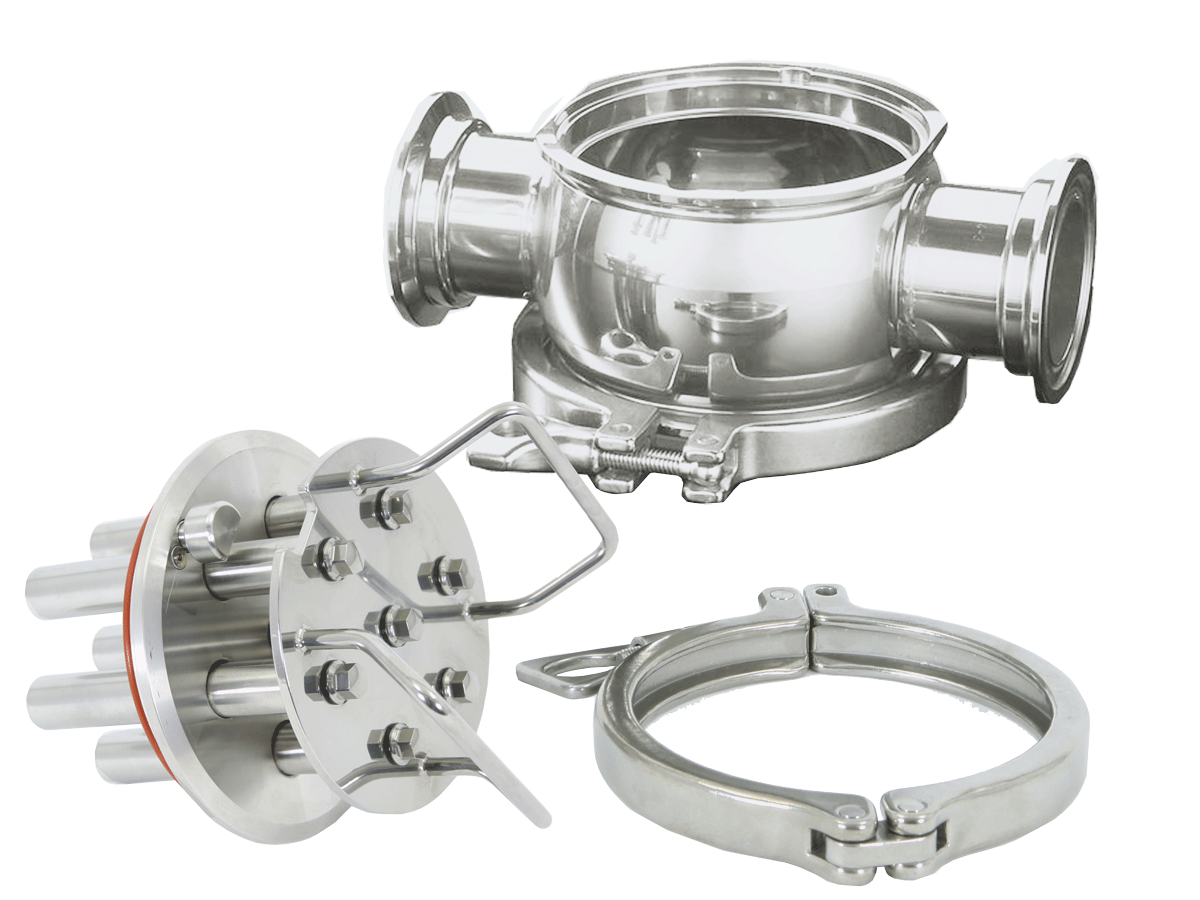

Advantages hygienic magnetic filter

✔ Modular magnetic inserts - multi- or single bar extractors offer up to 11,300 gauss in contact with the product

✔ Various flange and size options - easy to integrate into your existing process line

✔ Continuously welded construction - without gaps or edges, prevents bacterial growth

✔ Pressure-resistant up to 10 bar - suitable for pressurised liquid and powder flows

✔ Designed according to EHEDG guidelines - optimal food safety and cleanability

✔ Manual cleaning - fast, easy and robust in use

Why choose a hygienic magnetic filter?

Metal contamination is disastrous for processes that focus on food safety, product quality and hygiene. This magnetic filter offers an effective and reliable solution for capturing even the smallest ferrous contaminants down to 0.03 mm, such as stainless steel and iron particles. You prevent damage to equipment, guarantee a clean end product and meet the strictest requirements without compromising cleanability or production capacity.

Applications in industry

The hygienic magnetic filter is widely applicable within the food, pharmaceutical and cosmetic industries. Think of applications such as the production of dairy products, sauces, baby food, drinks, liquid medicines, gels and creams. In all these processes, the filter prevents product contamination, increases process reliability and contributes to a stable, hygienic production environment.

How does it work?

The liquid flows through the filter's stainless steel housing via a pressure line. Inside this housing are several powerful neodymium magnetic bars placed in smooth catch sleeves. As the product passes, these magnets attract and retain metal particles on the outside of the sleeves. The result is a continuously clean product flow, without clogging or pressure drop.

The cleaning process in 4 steps

- Remove the magnet unit from the filter housing

- Pull the magnetic bars out of the extractor

- Easily remove captured metal particles

- Post all back for new cycle

Thanks to its simple design, this operation only takes a few minutes, without tools.

Easy to install and maintain

The filter is designed with practicality in mind. Thanks to its compact, hygienic construction, it easily integrates into existing piping systems. The materials used - SS 316L and high-quality seals - are resistant to aggressive cleaning agents and high temperatures. This guarantees a long service life, even in intensive use.

Need advice or a quote?

Our specialists will be happy to help you select the right magnetic separator for your application. Get in touch or request a quote directly.

Hygienic magnetic filters are designed for the high demands in the food and pharmaceutical industry. They remove ferrous contaminants from 0.03 to 16 mm - such as stainless steel and iron - from liquid and powder flows in pressure lines up to 10 bar. The filters are cleaned manually and are available with multiple magnetic bars or one powerful single bar. This ensures a safe end product and reliable protection of your process installation.

(read more under the product overview)