Magnetic filters - industrial - semi-automatic

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

Application: Liquids and powders in pressure lines up to DN300

This very robust magnetic filter is suitable for many industrial applications where liquid mixtures and powders are transported in pressurized pipelines up to 10 bar. For example removing steel wire from paper pulp. Read more about this application in the news article on magnetic filter for paper pulp. We can calculate the precise pressure drop with these filters in your situation for gaseous or liquid products using our FEM software. The pressure drop depends on the physical properties of your product flow (viscosity) and its speed. Please contact us about this.

Construction & materials data

Short description

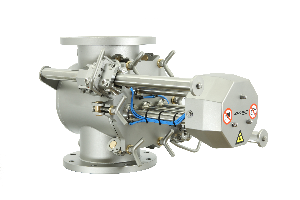

The industrial magnetic filter is a very robustly built filter, with flat flanges and a flat bottom. Equipped with pneumatically operated magnetic bars for semi-automatic cleaning. See explanation in tab 'Working principle'.

Click on a product variant to find the data sheet, drawings and other downloadable product information.

Summary of important specifications:

- Pneumatic magnetic bars Ø34 mm

- Magnet quality N-42SH, 9,400 gauss on tube Ø34

- Max. 10 bar / 140 °C

- Inlet/outlet: DN150 to D300 (EN1092-1)

- Finish: grit blasted

- Materials - in contact with product: AISI316(L)

- Material gaskets: Silicone acc. EC1935 / FDA

Working principle: Filtering & discharging of ferrous contaminants

How does the magnetic filtering work?

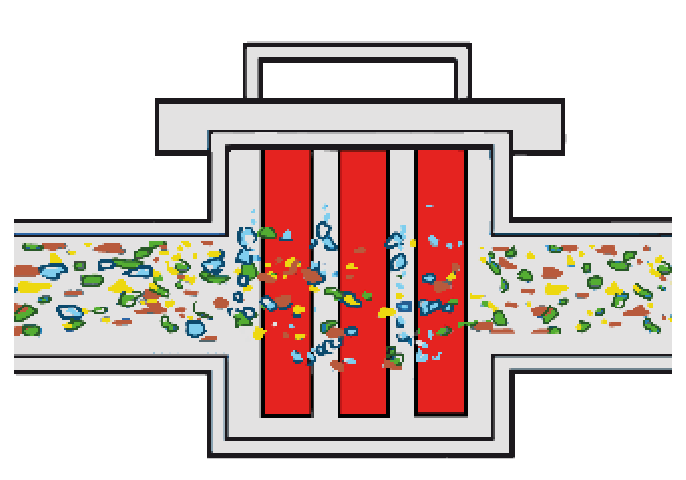

The magnetic unit with very strong neodymium magnetic bars is positioned in the middle of the product flow. The product with ferrous impurities passes several magnetic bars while flowing through the filter. The magnets attract passing ferromagnetic contaminants. The captured particles stick to the magnets, while the purified product flows further.

How does the cleaning / iron discharging work?

Cleaning of the magnetic rods is partly manually (over guide rods) and partly automatically (pneumatically controlled). Once the product stream is stopped, you pull the complete magnet unit out of the product channel over the guide rods. Then the magnetic rods are pneumatically 'blown' to the OUT position, at which point the Fe particles fall off of the tubes.

Cleaning / iron discharging sequence

- Stop the product flow.

- Loosen the srew connections of the magnet unit.

- Slide the complete magnet unit out of the housing.

- Slide the magnet unit out of the extractor unit.

Catch the ferrous particles that now will fall off the tubes and dispose them.

Wipe clean all parts with a soft cloth and - if necessary - a suitable cleaning fluid. - Slide the magnet unit back into the extractor unit.

- Slide the complete magnet unit assembly back into the housing.

- Re-tighten the screw connections.

- Restart the product flow.

Robust filter for general industrial applications without risk of bacterial growth. With these large diameters, the filters are too heavy to lift. Therefore, the cleaning is semi-automatic. For magnetic filtering of fine ferrous contaminants - such as stainless steel wear particles - from your liquid and powder flows in pressure pipes up to 10 bar.