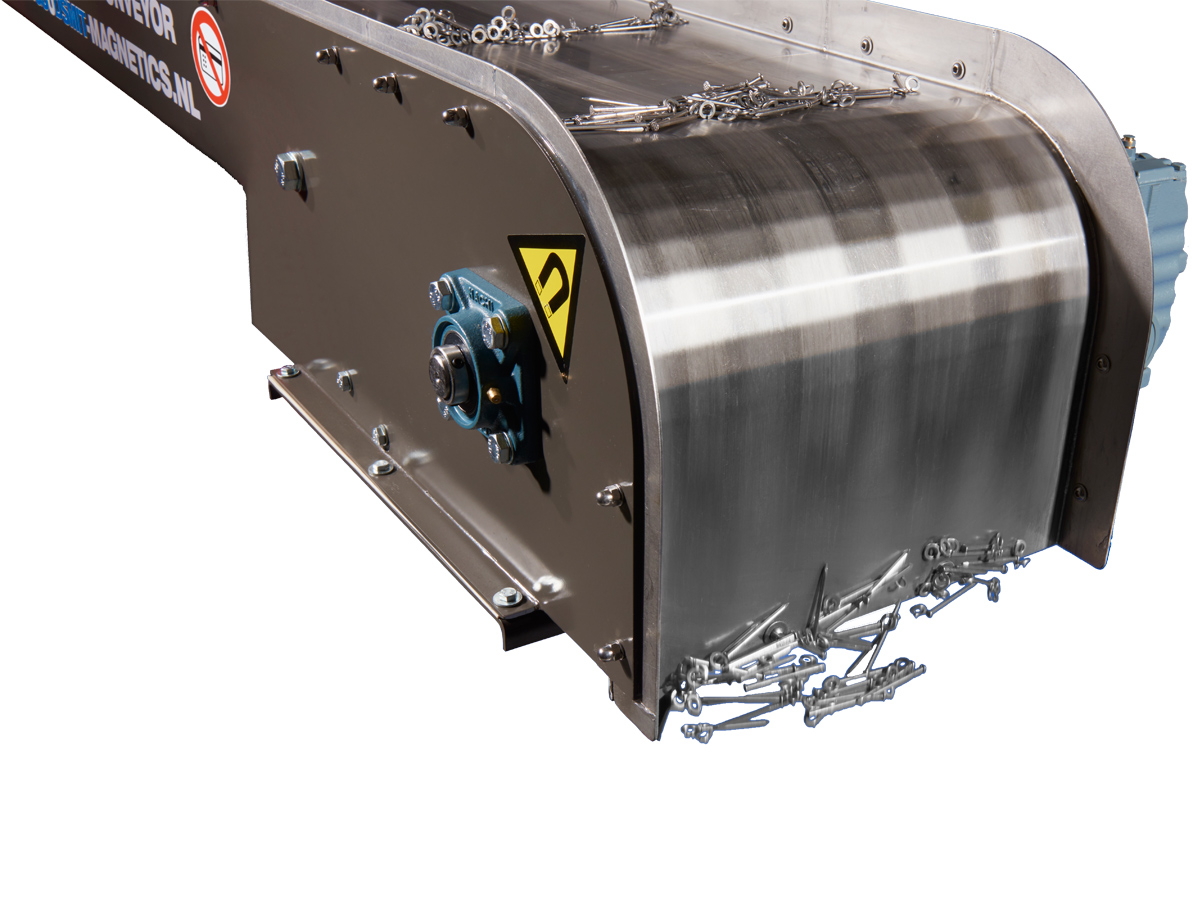

Magnetic slide conveyors type Swan neck

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

Application of closed magnetic slide conveyors

Magnetic slide conveyors are suitable for the disposal of steel parts such as punching waste, chips, nails, bolts, recycled materials or drilling waste in metal and steel plants and the sheet metal industry.

Advantages of a Swan neck slide conveyor

- no belt wear

- low maintenance

- no material can be left behind due to the closed construction

- no damage to product and conveyor belt

- dirt and moisture have no effect on operation

- completely closed; no moving parts on the outside

Features of a Swan neck slide conveyor

- maximum conveyor width: 575 mm

- conveyor length: up to 15 m as required

- maximum lift: 12 m

- capacity: 9 - 42 kg/min (punching waste Ø7x1 mm; 18m/min; with magnet spacing 600 mm)

- steep 60° lifting angle

Operation of a Swan neck slide conveyor

Below a stationary stainless steel slide plate are magnets mounted equidistantly on a chain. The chain is driven. Thus, the magnets move the steel parts over the slide plate and discharge them on the discharge side - at the desired height.

Magnetic slide conveyors are scrap conveyors - or chip conveyors - which, because of their closed construction, do not have any moving parts on the outside, as is the case of a conveyor belt. This makes them ideal for conveying sharp steel parts such as punch scrap, recycled materials, drilling swarf, nails or bolts. Application in metal and steel plants and the sheet metal processing industry - also in an oily environment.