Magnetic rails

Search results

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

No results found

-

{{filter.Description}}

({{filter.UOMDescription}})

No results found

Your results in: pages, products and documents

Scroll to see everything. Didn't find what you were looking for?

Try another search term or contact us.

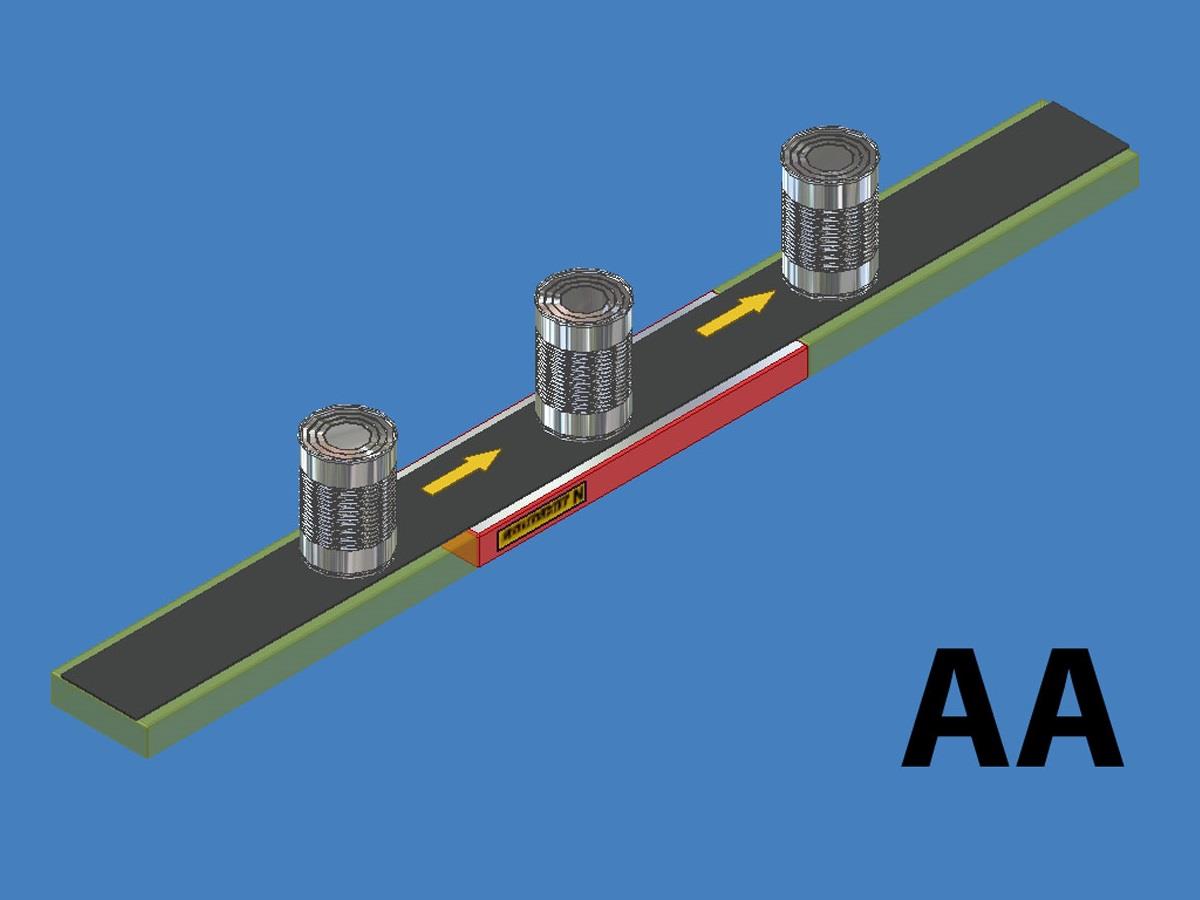

Application of magnetic rails for can transport

With magnetic rail components, you build your own magnetic transport system. This allows you to transport various product flows such as empty or full tin cans, lids, crown caps and so on. Figuring out the different types and the number of magnetic rails you need can be a challenge. We are here to help: contact our technical experts, they will be happy to assist you.

AA: straight-ahead version

For straight product flows with constant magnetic strength. Suitable for installation between other magnetic rails.

AB and AC: dissipating version

With dissipating magnetic field for transition from magnetic to non-magnetic transport and vice versa. The dissipating magnetic field guarantees uniform, trouble-free transition.

- Type AB for installation at the end of the magnetic conveyor

- Type AC for installation at the beginning

.jpg)

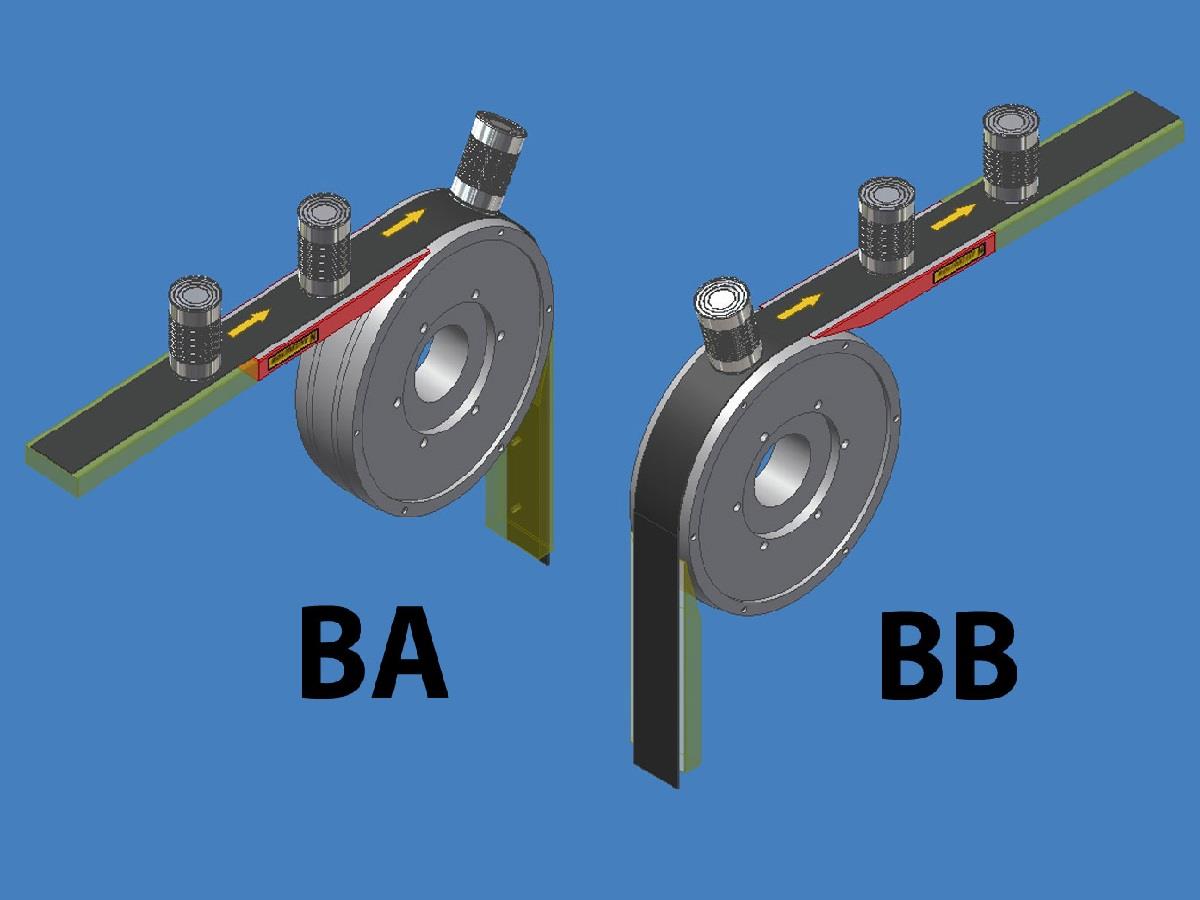

BA and BB: tapered version

With tapered design for optimal transition to a magnet roller.

- Type BA for installation in front of a magnet roller

- Type BB for installation behind a magnet roller

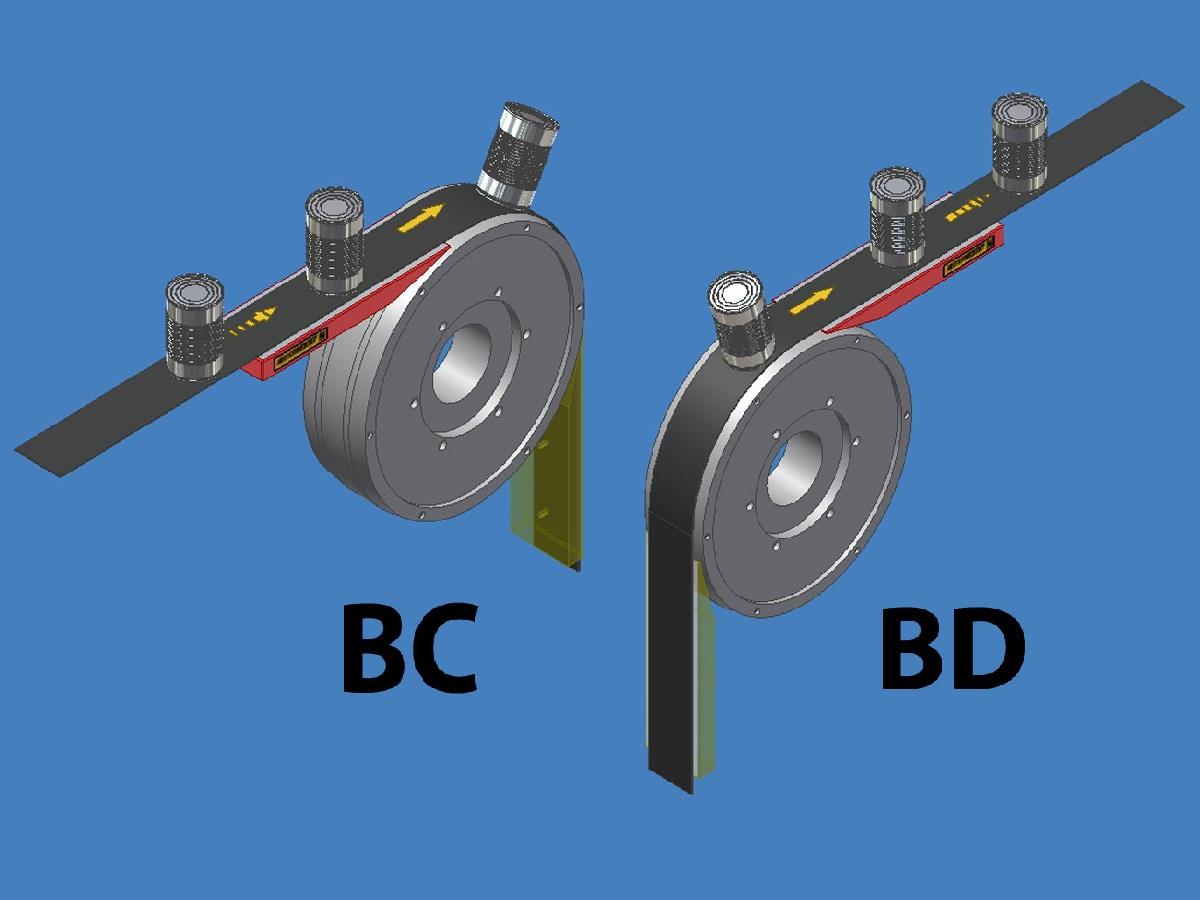

BC and BD: tapered and dissipating version

With tapered shape and dissipating magnetic field for transition from magnetic to non-magnetic transport and vice versa.

- Type BC for installation in front of a magnet roller

- Type BD for installation behind a magnet roller

Magnetic rails are used for straight product flows or flows with side in-feed or discharge. The most suitable magnetic rail version depends on the position in the conveyor system.

Various functions are possible. Magnetic rails are also available in a waterproof version.